How to select suppliers to customize backpacks?

1.The form of the market and the positioning of the product

A profound understanding of the market and a clear strategic positioning of the product will enable us to successfully complete a customized project. This article will lay a solid strategic foundation for the backpack customization project. By analyzing the current market situation and future trends, it will help the client define the target customer group and establish specific brand value goals.

1.1The upward trend and reasons of the global backpack market

- Nowadays, consumers prefer smart and multi-functional backpacks because they integrate many high-tech features, such as wireless charging, GPS tracking, RFID shielding, the Internet of Things, and integrated power supply, etc. This makes the backpacks no longer just simple tools for carrying things, but rather excellent assistants that support modern lifestyles.

- Everyone is increasingly paying attention to environmental protection, so backpacks made of recyclable materials (such as recycled bottles) and biodegradable materials are becoming increasingly popular. This is no longer an optional choice but something that companies must do, because it relates to whether the brand complies with environmental regulations and whether consumers will continue to support it.

- The ergonomic, comfortable backpack with adjustable waist and shoulder straps is in constant demand. Whether you are an office worker or an outdoor sports enthusiast, everyone values comfort

1.2Customer Segmentation and User Portraits

To succeed in the highly competitive market, it is crucial to conduct in-depth analysis and accurately identify the target customer groups. The main customer groups for custom backpacks can be classified into the following categories:

- Urban commuters: They carry backpacks every day in the city, seeking fashionable, functional and convenient storage solutions.

- Tourist: They need backpacks that are durable, have a large capacity and are equipped with multiple functions. They should be able to meet their needs for both short weekend trips and long overseas travels.

- Student: The students are looking for backpacks that offer good value for money, large capacity, and good appearance. They also need dedicated storage compartments, such as a padded compartment for the computer.

- Outdoor sports enthusiasts: They mainly need backpacks that are suitable for specific sports (such as hiking, camping), which are very durable, can hold water bags, and can be equipped with various small accessories.

- Tech enthusiasts: They prefer backpacks with advanced technological features, such as charging ports and anti-theft functions.

Attention! The market data shows that laptop bags, smart bags and student bags are selling very well now. This indicates that people’s lifestyles have changed.

One of the reasons is that remote working and hybrid working are becoming increasingly common nowadays. Schools also frequently use computers, so laptops that can be safely carried and charged have become even more popular.

Secondly, nowadays everyone prefers a “mobile lifestyle”. They believe that a backpack is not just for carrying things, but should also have functions such as anti-theft, data protection, and real-time tracking. This indicates that when making purchases, people place more emphasis on the experience and whether it can represent their identity, rather than just the practicality.

1.3. Create a unique brand story and value proposition

In a highly competitive market, merely having a good product is no longer sufficient. Project teams need to use a unique brand story to build a connection with the target customers. The brand should elaborate more on the underlying concepts of the product, so as to attract consumers with the same values. For instance, if a brand places great emphasis on sustainable development, it should highlight how the backpack is made from recycled materials or how it is durable.

The key to building trust lies in authenticity. Brands cannot just talk sweetly; they need to demonstrate their values through concrete actions, such as disclosing the production process, supporting charitable causes, or collaborating with environmental organizations. In this way, the backpack is no longer merely a product; it becomes more like an expression of one’s identity or lifestyle.

2. Product Design and Function Specification Analysis: Thorough refinement from concept to detail

The key to product design lies in transforming strategic planning into practical functions and details. This part will analyze each important component of the backpack product from an engineering and design perspective, ensuring that the final product achieves the highest level in terms of functionality, durability, and user experience.

2.1 Ergonomic Design: The Foundation of Comfort and Functionalit

Whether a backpack is comfortable mainly depends on its ergonomic design. A good backpack should be comfortable mainly based on the length of your torso, not your height. Therefore, the project team must ensure that the size of the backpack matches the user’s torso, and also pay attention to the following:

Weight distribution: The belt and the chest strap can distribute the weight on the shoulders to the buttocks, which is very important when carrying something for a long time or when carrying heavy loads.

Air circulation: By using a mesh back panel to separate the backpack from the back, it allows for better air circulation. This way, the back won’t sweat easily and it will be more comfortable to carry.

Internal frame: Many everyday backpacks have internal frames, such as plastic sheets or aluminum rods, which provide support and help you carry heavier items. Plastic frame sheets are relatively lightweight, while aluminum rods can offer solid support for heavier objects.

2.2 Material Selection: Both Art and Science

Selecting materials is a process that requires comprehensive consideration. It directly reflects the brand’s commitment to its target customers. The choice of fabric not only takes into account functional factors such as durability and water resistance, but also affects the cost of the product and the brand story. The table below provides a detailed comparison of the characteristics and suitable application scenarios of several common backpack fabrics.

| Fabric Type | Pros | Cons | Ideal Use |

| Nylon | Extremely durable, lightweight, abrasion-resistant, tear-resistant. | Degrades with prolonged sun exposure, poor UV resistance. | Outdoor, sports, and casual backpacks. |

| Polyester | Inexpensive, UV-resistant, waterproof, easy to dye, holds color well. | Slightly less durable than nylon, lower strength. | Casual, urban, and everyday backpacks. |

| Ripstop | Unique weave prevents tears from spreading. | Slightly higher cost. | Outdoor hiking, camping, and travel backpacks. |

| Canvas | Tough, durable, classic aesthetic, biodegradable. | Heavier than synthetic fabrics, poor water resistance. | Vintage or fashion lifestyle brands. |

| Cordura® | Extremely resistant to abrasion, tearing, and scuffing. | High cost. | Tactical, military-grade, or heavy-duty outdoor gear. |

| Ballistic Nylon | Military-grade durability, high strength, abrasion-resistant. | Heavy and high cost. | Backpacks for extreme conditions, such as military or industrial use. |

2.3 Select the appropriate fasteners and accessories

The selection of fasteners and accessories is very important as it can affect the lifespan of the product and the user experience. Poor-quality zippers and buckles are the most prone areas for damage in backpacks.

Zippers: Make sure to use the right type of zipper. YKK is the leader in the zipper industry. Its production standards and quality control are excellent, and it is highly reliable. YKK’s products include metal zippers (suitable for thick fabrics), nylon zippers (flexible, durable, and lightweight) and resin zippers (lightweight, with a wide range of colors). There are also some special zippers, such as AquaGuard waterproof zippers, which can provide better protection for specific types of backpacks.

Fasteners and clasps: There are various types of fasteners for backpacks, including side-release clasps, U-shaped clasps, D-ring clasps, and ladder clasps, etc. These fasteners can be made of plastic (such as nylon, polypropylene, ABS), metal (such as aluminum, stainless steel, titanium), or a combination of materials. Plastic fasteners are lightweight and have good strength, while metal fasteners are more durable and sturdy, but they are heavier and may rust. Choosing good fasteners and accessories will increase costs, but it can significantly improve the durability and reliability of the product, thereby reducing customer complaints, returns, and enhancing the brand’s reputation.

2.4 Integrating Modern Functions: Technology, Security and Versatility

The current backpack design is no longer just for carrying things. It also incorporates features such as technology, safety and versatility to meet the needs of different people. These features include:

- Soft-padded laptop compartment: Provides protection for electronic devices. Nowadays, this feature is commonly found in the backpacks of both students and office workers.

- Anti-theft zippers and RFID shielding pockets: By concealing the zippers and using materials that can block RFID signals, users’ belongings and personal information can be protected.

- Water bag compartment and pipeline holes: Specifically designed for those who enjoy outdoor activities, to facilitate their carrying of water bags and replenishing water during the activities.

- Modular accessory system: For example, the ice pick ring, binding strap, and lanyard on the hiking bag, as well as the MOLLE system on the tactical backpack, allow users to add or remove accessories according to their own needs.

2.5 Durability: Both the design and production processes need to take durability into account.

The durability of a backpack is very important. This is not just a matter of the material; both the design and the production need to be taken into consideration.

Strengthened stitching: For areas that are prone to stress, such as straps, handles, and seams, double or triple stitching should be used, followed by knotting for reinforcement. Only in this way can they withstand the daily pulling and weight.

Thickened bottom: The bottom and corners of the backpack often come into contact with the ground, which is the most prone to damage. By adding an extra layer of fabric, a cushion, or a hard material like EVA foam, along with a protective foot pad, it can effectively prevent wear and keep the backpack dry.

3. Production and Cost Planning: Financial Analysis from Sample to Mass Production

After the design plan is determined, the project team needs to formulate detailed production and cost plans. This section will introduce the financial model and key processes for custom backpack production, helping everyone understand the cost composition and making business decisions based on the order quantity.

3.1 Detailed Explanation of Customized Backpack Production Process

The complete production process of a custom backpack typically involves the following main steps:

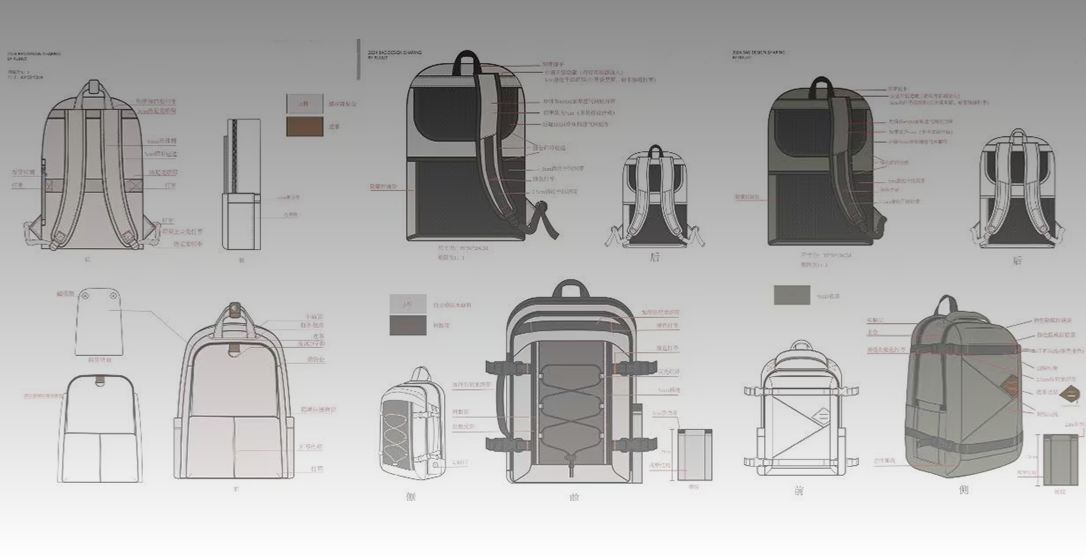

- Technical design and prototype production: First, the design ideas are transformed into detailed technical drawings and specifications. Then, the factory will produce a prototype based on the drawings to test the shape, size and functions of the backpack.

- Pattern making and fabric cutting: Create precise templates for each component of the backpack. Next, use industrial machines (such as die-cutting machines or laser cutting machines) for precise cutting, minimizing material waste as much as possible.

- Brand printing and decoration: Print the brand logo on the cut fabric, such as by embroidery, screen printing or embossing.

- Seaming and Assembly: Skilled workers use industrial sewing machines to stitch the fabric together, and then attach zippers, pockets, shoulder straps, and padding. In areas subjected to high stress, double stitching is usually employed to enhance the strength.

- Quality inspection and durability testing: After each batch of backpacks is assembled, they must undergo strict quality inspection and durability testing to ensure they meet the established standards.

3.2 Cost Composition and Financial Model

The cost of custom-made backpacks is determined by several factors. After analysis, the main costs come from:

- Raw materials: This is the largest component, accounting for 40% to 60% of the total cost, including fabrics, hardware, thread, and fillers. For instance, a technological fabric costs approximately $8 – $15 per piece, and an EVA foam board costs about $7 – $14 per piece.

- Labor cost: Accounts for 20% – 30% of the total cost, including cutting, sewing, assembly and final finishing. The wage levels in different regions will directly affect this portion of the cost.

Mold and sample development: accounts for 10% – 15% of the total cost. The initial investment may range from $2,000 to $10,000 depending on the complexity of the design. The cost of making a sample is usually around $200 – $500. - Factory management: Accounts for 10% – 15% of the total cost, including rent, utilities, equipment depreciation, and administrative expenses, etc.

Note that the output has a significant impact on individual costs. For instance, the cost of molds will be shared as the output increases, thereby significantly reducing the individual cost.

3. 3 The Impact and Considerations of Minimum Order Quantity (MOQ)

Regarding backpack customization, there are two different customization methods, and the requirements for minimum order quantity (MOQ) vary significantly. This is something that startup companies must understand clearly.

- Modification of existing products: The supplier provides ready-made backpacks. Customers can add their logos (such as embroidering flowers or screen printing) or choose different colors. This method has a very low MOQ (Minimum Order Quantity), and some even require only 1 or 10 units. It is suitable for promotional gifts or small-scale events. The advantage is that the initial investment is low and the inventory pressure is small.

- From scratch design: The client provides the design drawings or ideas, and the factory starts from scratch. This method has a relatively high upfront cost, such as mold making, sample production, and the creation of technical documents. To spread out these costs, the factory usually sets a relatively high MOQ (Minimum Order Quantity), for example, 250 pieces for each style and each color.

Although designing from scratch can create a unique brand, the investment and inventory risks are much higher compared to making minor changes to existing products. The difference in MOQ (minimum order quantity) is so significant (1 vs 250), which is a crucial point that the project party needs to consider and make a wise choice from the very beginning.

4. Supplier evaluation and partnership management: Ensuring quality and compliance

Selecting the right suppliers is of vital importance for the success of a project. The project team should establish a comprehensive supplier evaluation system, seek reliable partners, and establish long-term cooperative relationships.

4.1 Framework for Comprehensive Evaluation of Suppliers

When evaluating suppliers, one should not merely focus on the price; instead, they should pay attention to the following three main aspects:

1. Skills and Technologies:

- Production Capacity:Can the supplier handle orders of various sizes? Can their production line and the number of workers meet the changing demands?

- Technical Level: Does the supplier have good technologies such as laser cutting, heat sealing, and computer embroidery to ensure product quality and production efficiency?

- Delivery Time:Does the supplier’s time for processing orders, customizing products, and shipping meet our requirements?

2. Quality and Compliance:

- Quality Control:Does the supplier have a comprehensive quality inspection process? What is their defect rate?

- Certification:Does the supplier have relevant industry certificates, such as ISO 9001 (Quality Management), BSCI (Business Social Responsibility Initiative), and OEKO-TEX (Ecological Textile Standards)?

- Traceability: Can the supplier provide complete production records, including materials, components, and production steps, so that the source can be traced in case of any issues?

3. Finance and Ethics:

- Financial Status:Is the supplier’s financial situation sound? Does it have the ability to continuously invest funds and maintain the partnership?

- Business Ethics:Is the supplier compliant in terms of human rights, employment practices, environmental protection, and business ethics?

4.2. Ensure ethical practices and supply chain transparency

When evaluating suppliers, one should not only consider price and quality, but also their responsibilities towards society and the environment. Large enterprises like Hershey have already made human rights, labor, the environment and business ethics as essential prerequisites when selecting suppliers. This indicates that industry standards are becoming more transparent and more responsible.

For new brands, adopting these standards is not only a moral obligation, but also a good way to build brand trust and attract environmentally-conscious consumers. Therefore, even for newly established companies, they should incorporate factory audits and third-party certifications like SGS into their evaluation process to verify whether suppliers are compliant

4.3. Risk Management and Long-Term Cooperation Strategy

Establishing a long-term cooperative relationship with suppliers is of great significance. Through regular inspections, establishing smooth communication channels, and clearly defining improvement plans, we can jointly address potential risks and promote continuous progress. This cooperative model helps ensure the continuous stability of product quality and lays a solid foundation for future business development.

5. Summary and Next Steps Plan

5.1 Report Summary

Making custom backpacks is, to put it simply, a rather complicated task. From market research, product design to production and supply chain, all of these need to be carefully planned. To do it well, remember these points:

- Identify the Position: Thoroughly study the market and see what is currently popular (such as intelligence and environmental protection), then create your brand characteristics based on your target customers (such as office workers, tech enthusiasts).

- Product Quality: Every detail, from ergonomic design to material selection and small accessories, affects the user experience.

- Calculate the Costs: Clearly understand the costs. Depending on the different order quantities, decide whether to modify the existing product or completely redesign it.

- Manage the Supply Chain: Establish a strict supplier evaluation system. Not only consider price and quality, but also check if they are reliable and meet ethical standards, and establish long-term cooperative relationships

5.2 Specific Actions and Phased Plans

In order to carry out this project step by step, it is recommended to follow the following plan:

- Phase 1: Set Strategy (1-2 Weeks)

Conduct market research and analyze both domestic and international markets.

Identify your primary customers and understand their needs.

Develop a unique brand story. - Second stage: Product development (3-8 weeks)

Complete the functionality and appearance design of the backpack.

Based on the design, determine the materials such as fabric, lining, fasteners, and zippers.

Find suppliers to make samples and continuously adjust and test. - Phase 3: Select suppliers and prepare for production (8-12 weeks)

Use the evaluation system in the report to select suitable suppliers and negotiate cooperation with them.

Visit the factory to assess their production capacity, quality control, and compliance.

Select the suppliers and sign the contracts. - Fourth stage: Mass production and launch (more than 12 weeks)

Start production based on the minimum order quantity.

Continuously conduct quality control during the production process.

Develop packaging and transportation plans to ensure that the products are delivered to the customers on time.