Your Professional Leather Bags Manufacturer

If you are looking for a professional Leather Bags manufacturer, SENHAN LEATHER is your premier choice. We operate a 4,000 sqm workshop with over 200 skilled workers, first-class modern production equipment, and 12 production lines. Our monthly production capacity reaches up to 60,000 pieces, enabling us to easily handle both small and large orders.

We can assist you in manufacturing a wide range of leather products, including leather backpacks, leather handbags, leather clutches, leather crossbody bags, leather cosmetic bags, leather laptop bags, leather pet bags, and leather travel bags, catering to various industries such as fashion, healthcare, outdoor sports, school, charity, pets, and cosmetics.

Senhan Leather Bags By Features

SenHan Group is a professional leather goods manufacturer, designing high-end and custom-made leather goods for both men and women. As a leather goods factory, we offer production of various styles of handbags and we will be the best leather goods manufacturing enterprise in your mind.

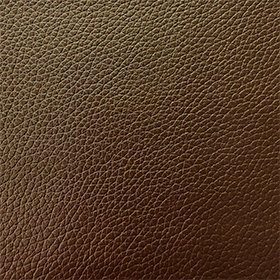

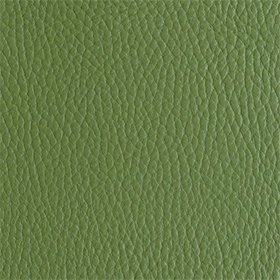

Choose Your Leather Bag Material

As an outstanding manufacturer and wholesaler of leather bags, the SenHan Group uses a variety of leather materials to produce different products. We are one of the best leather bag manufacturers in China, using natural leathers (such as cowhide, sheepskin, crocodile skin, ostrich skin and snake skin) as well as synthetic leathers (such as polyurethane leather, PVC leather and microfiber leather) to manufacture high-quality leather bags.

Cowhide Bag

Cowhide Bag Crocodile Skin Bag

Crocodile Skin Bag Sheepskin Bag

Sheepskin Bag Suede Bag

Suede Bag PU Leather Bag

PU Leather Bag PVC Leather Bag

PVC Leather Bag

Why Senhan BLeather Bags

As a professional Leather Bags manufacturer, SenHan does not betray its clients’ trust and places great emphasis on quality control and the development of its production capabilities, aiming to provide customers with the highest quality Leather Bags.

You can choose from over 200 types of fabrics.

We monitor the entire production process and conduct strict quality checks at every stage.

You can choose sustainable and recycled materials.

We have obtained multiple certifications, such as BSCI, ISO, and AQL.

The minimum order quantity (MOQ) is 300 pieces.

Logo effects, size, color, material, and more can be customized according to your needs.

Typically within 4-8 weeks.

Custom Logo/Slogan Make Your leather bags Stand Out

SenHan can customize the logo for your leather bag. There are two main ways to create the brand logo for your handbag: on the leather, you can use heat pressing (colorless), gold stamping, silver stamping or colored stamping techniques; on the hardware accessories, it can be achieved through engraving, laser cutting or mold making processes.

Complete Production Line For Your leather bags

We are a comprehensive supply chain, covering design drafts, samples, raw material procurement and inspection, production planning and SOP, mass production, finished product quality inspection, and packaging. The entire production process can be monitored to help you better control the quality and production time of your Leather Bag.

Our skilled product development experts, production managers, and quality engineers will focus on every detail and stitch to provide you with better advice and high-quality Leather Bag.

Professional Leather Bags Manufacturer in China

SenHan owns a 4,000 sqm workshop with over 200 skilled workers, first-class modern production equipment, and 12 production lines. Our monthly production capacity reaches 60,000 pieces, with an annual output exceeding 7 million pieces. Our dedicated product development experts, production managers, and quality engineers pay close attention to every detail and stitch, ensuring excellent control over Leather Bag quality and production time.

Our Eco-Friendly Material

Different eco-friendly materials have different properties. What kind of Leather Bag do you need?

The main raw materials are plant or agricultural waste, sourced sustainably. The production process results in less greenhouse gas emissions and water consumption. It is biodegradable, wear-and-scratch resistant, has a low material density, and is lighter than PVC leather. It is also antibacterial and mildew-resistant, soft to the touch, has good breathability, high color fastness, and can be processed with various techniques. This material is suitable for fashion commuter Leather Bag, outdoor sports Leather Bag, and more.

100% plant-based, animal-free, and low-carbon production. It is biodegradable, scratch-resistant, has a lower density and is lighter than traditional leather, and is basically waterproof. It has good breathability, a unique texture from plant fibers, and can mimic high-end textures with strong customization capabilities. It may have natural imperfections, making it more suitable for commuter fashion Leather Bag, outdoor Leather Bag, etc.

Made from recycled waste plastic, it has multiple environmental certifications and is non-toxic and safe. It has low density, is lightweight, and is highly wear-resistant due to its high-density weave. It is also cold-resistant, waterproof, anti-static, requires less water for dyeing, and has high colorfastness. It can simulate various textures but has poor breathability, making it more suitable for outdoor heavy-duty Leather Bag, daily commuter Leather Bag, etc.

No chemical additives, biodegradable, non-toxic, and safety-certified. It is breathable, moisture-absorbent, soft to the touch, and skin-friendly. Its wear resistance is basic and wrinkle resistance is weak, requiring an extra coating for a waterproof effect. It has a natural cotton and linen texture and can be customized with various techniques, making it more suitable for daily commuter Leather Bag, luxury Leather Bag, etc.

Testimonials

Yes, our leather bagS have obtained certifications such as GRS, Bluesign, GOTS, and FSC. Sustainable materials are available for selection, including organic cotton, cellulose fiber, polylactic acid (PLA), RPET, ECONYL, and perfluorochemical-free (PFC-free) materials. For zippers and buckles, we use non-toxic materials or recycled metal.

In the Leather Bag production process, we adopt low-carbon manufacturing, clean energy, and zero-waste designs to reduce our environmental footprint. As a member of the global village, we are committed to doing our part.

- Once the sample is confirmed, it will be sealed in a sample lock bag. We will then proceed with mass production of your Leather Bag based on the confirmed sample.

- Our raw material purchasers will inspect the quality, color, and quantity of all materials before they are moved to the warehouse.

- We have a professional finished product quality inspection workshop. Leather Bag that pass the inspection will proceed to the next step of packaging, while defective ones will be sent back to the production line for rework or modification.

- We will also check the packaging before the leather bags are shipped out.

Typically, if your quantity is between 300 to 5,000 pieces, the production time for leather bags is about 4-8 weeks. However, factors like quantity, technology, design, materials, and hardware can also affect the timeline. Please let us know your quantity and specifications so we can provide a detailed estimate for the Leather Bag production time.

The production time for samples is 15-20 days.

We can help you produce Leather Bag in thousands of colors, but this is also related to the materials and technology. For example, natural materials like leather, cotton, and linen are more difficult to dye than other materials. Please contact us to provide your color requirements and check our leather bags color card.

So far, our leather bags factory has obtained certifications including Quality, ISO, BSCI, AQL standards, SMETA, Sedex, Disney, SGS, Ethics Matter, and QIMA.

Our minimum order quantity (MOQ) for leather bags is 300 pieces. However, if you order 500 pieces or more, we can provide a free sample after receiving the deposit and before mass production. Therefore, if you are looking to place a trial order, we highly recommend 500 pieces over 300.