Preface: The Strategic Value of Load Stability for Bag Brands

In today’s global bag market, the crossbody bag has become a core item for city commuting, outdoor travel, and daily leisure because it frees your hands and looks stylish. However, for end consumers, a common and frustrating pain point is the sliding strap problem. This sliding is not just about the strap falling off the shoulder, but also includes the adjustment buckle loosening automatically under weight. For brand owners and corporate customers looking for customized production, how this detail is handled directly decides the product return rate, user loyalty, and brand market position.

As an industry leader with 11 years of bag manufacturing experience, SENHAN deeply understands that stability is not an accidental decoration. It is the result of complex material science, mechanical structure, and precision manufacturing. The technical challenge of strap sliding involves biomechanics, material friction, and precision mechanical engineering. This article will reveal from a manufacturer’s professional perspective how modern factories solve the stability problem through technical innovation and strict process, showing how to create value for global customers through customized services.

Chapter 1: Deep Analysis of Mechanics and Biomechanics of Strap Sliding

1. Influence of Human Shoulder Anatomy on Loading

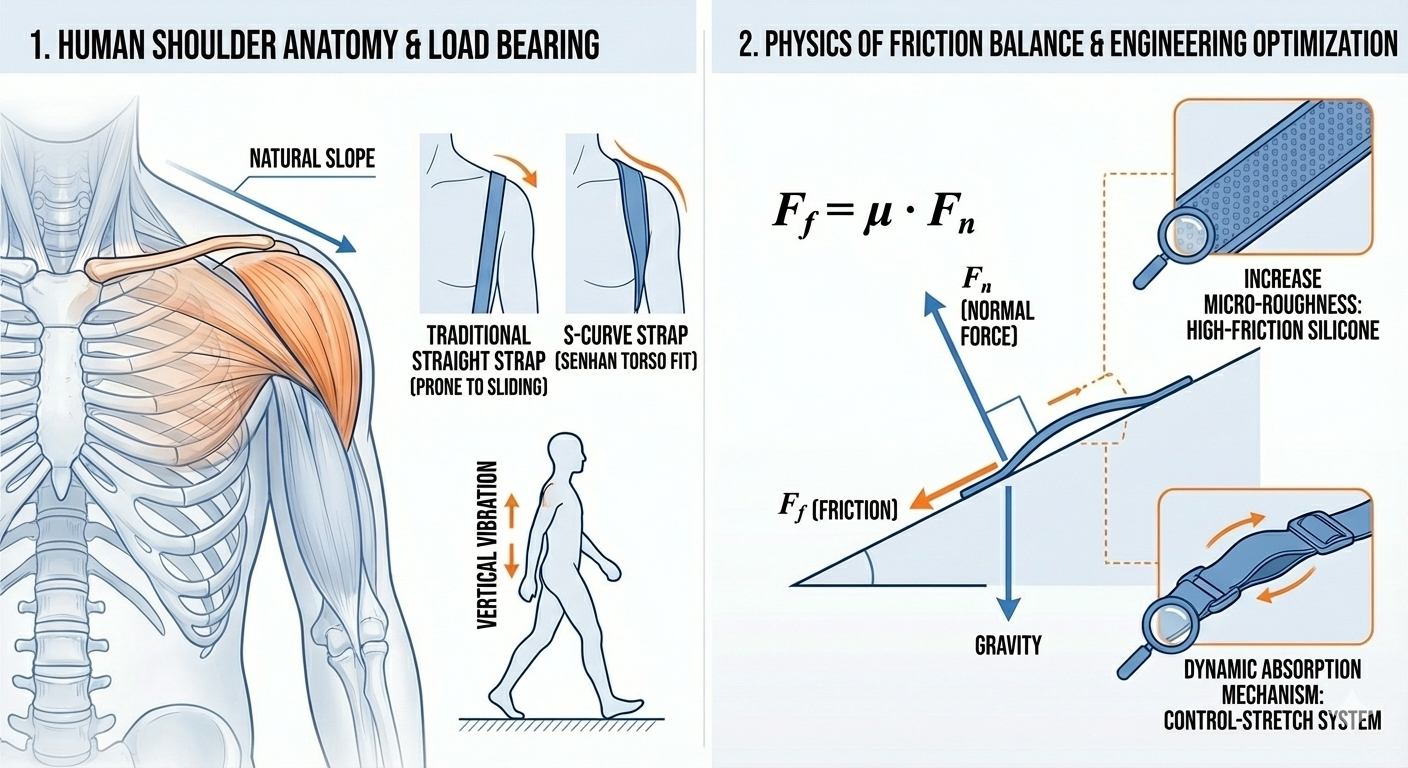

From a biomechanical perspective, the human shoulder is not an ideal horizontal platform. The slope formed by the clavicle and deltoid muscle has a natural gradient, which means any object placed on it faces the challenge of gravity components. When the user is in a dynamic state—such as walking, running, or cycling—the vertical vibration of the body creates kinetic energy, which periodically changes the normal force of the strap on the shoulder.

In traditional straight strap designs, the force points are often concentrated in a small area on the outside of the shoulder. Professional manufacturing factories will introduce Torso Fit testing during the R&D stage. Research shows that for female or narrow-shouldered users, the S-Curve design can effectively avoid the chest and fit the shoulder curve more closely than traditional J-shape or straight straps, thus greatly reducing the sliding probability.

2. Friction Balance Equation from a Physics Perspective

The main secret to solve sliding is keeping the friction force (Ff) always bigger or equal to the gravity part in the slope direction.

The formula Ff = μ × Fn shows that increasing the friction coefficient (μ) or the normal force (Fn) are the only two ways. However, too much normal force will cause shoulder pain and neck fatigue. Therefore, excellent manufacturers optimize this equation through:

Improving surface microscopic roughness: By introducing silicone, rubber, or anti-slip backing with high friction characteristics on the inner side of the shoulder pad.

Dynamic absorption mechanism: Introducing a Control-Stretch System to convert sudden vibration energy into elastic potential energy, avoiding friction dropping to zero due to instant weightlessness.

| Scenario Type | Core Mechanical Challenge | Sliding Cause Analysis | Recommended Solution |

| Business Commute | Smooth clothing fabric with very low friction | Silk or wool fabrics make μ very small | Silicone dot coating or sticky synthetic fiber |

| Cycling / Fast Action | Violent multi-directional centrifugal force | Large body tilt changes the force vector | Third Leg Stabilizer (three-point system) |

| Heavy Load Travel | Adjustment failure caused by static pressure | Micro-creep between buckle and webbing under long-term tension | Nylon webbing with stainless steel claw buckles |

Chapter 2: Solving Sliding from the Raw Material Side: Webbing and Coating Technology

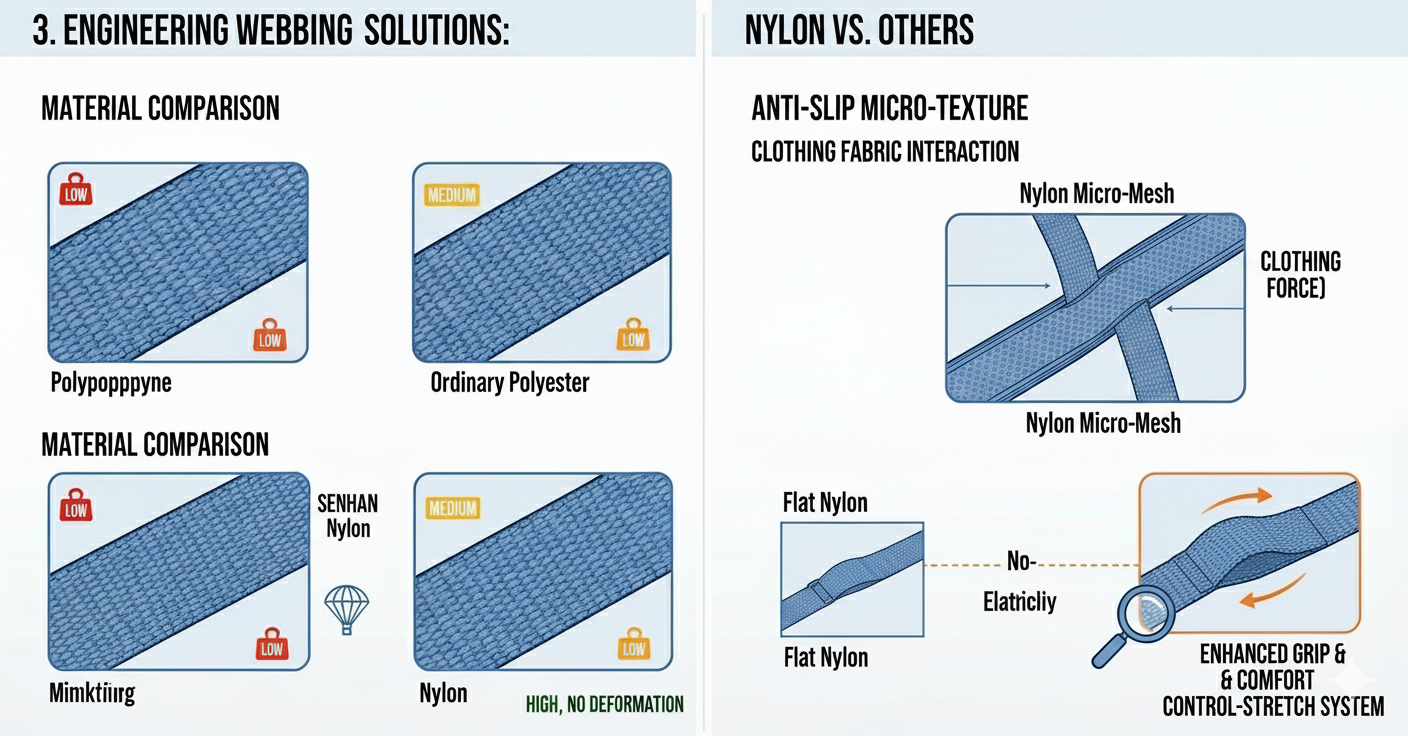

1. Industrial Advantages of Nylon Webbing: Balance of Strength and Friction

In the bag industry, webbing is the skeleton of the strap system. SENHAN usually recommends Nylon instead of Polypropylene or ordinary Polyester in customized solutions. Nylon webbing was born from parachute technology in WWII, and its high tension (up to 3000-6000 lbs per inch) ensures no deformation under heavy load.

From an anti-slip perspective, nylon fibers can better simulate the texture of clothing fabrics, forming a microscopic mesh. SENHAN provides flat and tubular nylon options. Tubular nylon has better thickness and elasticity after being flattened, providing a better grip feeling when used as a shoulder strap.

2. Silicone Anti-slip Process: Coating, Dotting, and Heat Curing

To stay stable on smooth fashion fabrics, modern factories introduced advanced Silicone treatment technology.

Material Preparation: The factory uses two-component liquid silicone rubber (A and B glue) mixed by high-precision digital scales to ensure the best hardness after curing.

Dispensing Process: Using automated dispensing machines to apply liquid silicone in dots or specific patterns (like honeycomb) on the inside of the webbing. This discrete distribution maintains breathability.

Curing: The coated webbing passes through a specific temperature oven. SENHAN’s production line ensures the silicone and fiber form a Mechanical Interlock, meaning the anti-slip layer will not peel off even after long-term friction and washing.

3. Anti-slip Characteristics of Eco-friendly Materials

With the rise of ESG standards, more customers ask for eco-friendly materials. SENHAN leads in sustainable development with GRS, GOTS, and FSC certifications.

Recycled Nylon (ECONYL) and RPET: After high-density weaving, their friction coefficient and tensile strength are fully comparable to virgin materials.

Bio-based Leather: Made from agricultural waste, its natural fiber structure has higher surface roughness than synthetic PU.

Cactus Leather: Due to the uniqueness of plant fibers, it not only has a leather texture but also performs exceptionally well in breathability and anti-slip for business bags.

Chapter 3: Manufacturing Practice of Ergonomic Geometric Design

1. Structural Development of S-Curve Straps

The fundamental reason for strap sliding is often that the design does not fit human engineering. For a professional factory, designing a non-slip crossbody bag starts with Pattern Making.

SENHAN’s R&D team recommends the S-Curve strap for high-spec custom orders. This design simulates the anatomical curve of the shoulder, making the strap produce an inward force at the clavicle, naturally resisting the tendency to slide off.

2. Load Distribution System and Internal Stretch Control

High-end factories like SENHAN add multi-layer structures inside the shoulder pads:

Middle Layer (Anti-stretch core): Usually made of heavy-duty nylon webbing for load stability.

Inner Pad (Shock absorption): Using closed-cell foam or Neoprene, which can absorb kinetic energy during walking, reducing the perceived load by about 50%.

- Outer Layer (Lycra binding): Using soft Lycra to prevent hard materials from cutting into the neck or shoulder, improving comfort and reducing the user’s need to frequently adjust the bag position.

| Performance Index | S-Curve Strap | Traditional Straight (J-Strap) | Conclusion |

| Narrow Shoulder Fit | Very High (Tight fit) | Low (Easy to slide from edge) | S-shape is better for Asian and female users |

| Pressure Uniformity | Excellent (Distributed to torso) | Average (Concentrated on top) | S-shape eliminates local pain points |

| Dynamic Stability | Excellent (No shift in motion) | Medium (Needs frequent manual adjustment) | S-shape reduces displacement through geometry |

| Recommended Load | 25 – 30 lbs | 20 – 25 lbs | S-shape supports higher comfortable load |

Chapter 4: Mechanical Locking and Auxiliary Stability Systems

1. Engineering Design of the Three-point Stabilizer Strap

For users who need zero shake (like city bikers or photographers), friction alone is not enough. This leads to the mechanical solution—the Third Leg Stabilizer.

This design adds an auxiliary connection point at the base of the bag, using a removable sub-strap crossing the underarm to connect to the main strap buckle. This triangular mechanical structure completely locks the rotation of the bag. SENHAN pays special attention to the stitching strength of connection points, usually using Box-X Stitch or Bar-tacking.

2. Application of Advanced Buckles and Magnetic Technology

Ladder Locks and Claw Buckles: Professional manufacturers like SENHAN choose heavy-duty metal claw buckles (Stainless Steel Swivel Clips) with tensile strength up to 980 lbs.

Magnetic Centre-Push Buckle: Unlike traditional plastic buckles, magnetic buckles provide instant locking and one-hand release. Their internal precision structure ensures automatic biting when loaded and will not crack due to fatigue.

Chapter 5: Quality Assurance and Customization Process Under SENHAN System

1. Precision Manufacturing from 4000sqm Factory and 200 Workers

Solving strap sliding is not just a promise; it relies on strong industrial infrastructure. SENHAN has a 4000 square meter modern factory with over 200 skilled workers and 12 parallel production lines.

Design Workshop: Designers input mechanical parameters into computers to generate precise laser cutting paths, ensuring the strap shape is perfect.

Sample Lab: Before mass production, every custom sample undergoes at least 15-20 days of testing, including vibration simulation under full load to check for micro-sliding.

2. Full Process Quality Control and International Certification

As an integrated manufacturer exporting to over 80 countries, SENHAN sets QC points in every process.

Raw Material Inspection: We check webbing color, thickness, tensile strength, and anti-corrosion treatments.

Sample Lock Bag Mechanism: Once the customer approves the sample, we seal it in a lock bag as the only standard for mass production. This eliminates performance deviation between batches.

Final QC (AQL Standard): Before entering the warehouse, our team performs random inspections according to ISO and AQL standards. Any product with buckle failure or uneven coating will be sent back for rework.

| Category | Detailed Data | Strategic Meaning for Customers |

| Factory Area | 4,000 – 8,000 sqm | Supports large orders and material storage |

| Monthly Output | 60,000 pieces | Ensures on-time delivery despite supply chain fluctuations |

| Staff Size | 200+ Skilled Workers | Guarantees high quality in manual finishing steps |

| Certifications | BSCI, ISO9001, GRS, Sedex | Lowers compliance risk and meets eco-standards |

| Material Options | 200+ Types | Provides unlimited texture and performance choices |

Chapter 6: Industry Outlook: Integration of Intelligence and Sustainability

1. Idea of Intelligent Anti-slip Systems

Future anti-slip might go beyond physics. For example, embedding nano-sensing fibers in the strap to monitor shoulder force balance in real-time. SENHAN’s R&D team is already exploring using lightweight carbon fiber materials to enhance strap structural rigidity.

2. Anti-slip Innovation under Zero-Waste Design

Eco-friendly should not mean losing performance. SENHAN is promoting Zero-Waste Design by optimizing layouts to reduce webbing waste, while using recycled industrial waste to develop new high-grip pads. High-density recycled polyamide has made new breakthroughs in tear resistance and anti-slip performance.

3. Customized Solutions for Different Climates

Global needs are diverse. SENHAN’s customization includes fine-tuning anti-slip details. For example, for cold regions like Northern Europe, we choose rubber materials that stay flexible at -40 degrees. For tropical regions, we strengthen anti-mold treatment and breathability. This climate-based advice is a high-value asset from our 11 years of expertise.

Conclusion: Deep Customization is the Ultimate Path to Solve User Pain Points

In the crossbody bag market, beauty might get the first click, but stability is the key to repurchases and word-of-mouth. Solving the sliding problem is a systematic project covering material physics, 3D modeling, and strict factory QC.

From SENHAN’s view, a factory is not just a production tool, but a realizer of the customer’s brand ideal. When you choose SENHAN as your manufacturer, you get more than a bag—you get a mobile carrying system tested thousands of times, using S-Curve patterns and eco-friendly technology. Whether you need 300 pieces for a startup or tens of thousands for global retail, SENHAN can help your brand win against competitors in every detail.

If you are looking for a partner who understands and can cure technical pain points like strap sliding, SENHAN welcomes you to visit our production base or contact our expert team to start a new chapter in high-quality bag customization.